Polyoxymethylene (POM)

POM, also known as acetal, polyacetal and polyformaldehyde, is an engineering thermoplastic used in precision parts which require high stiffness, low friction and excellent dimensional stability. As a tough, solvent and fuel resistant plastic it is used for gears, bearings, window guides, speaker grills, zips, lighters, aerosol valves, fasteners and furniture components.

- History

- Properties

- Applications

- Processes

- Recycling

- Faq

History

1920: Polyoxymethylene was discovered by Hermann Staudinger

Late 1950s/early 1960s: Commercialisation following MacDonald’s (DuPont) success at synthesizing a version in 1952.

1959: production of a heat stable POM homopolymer invented by Dal Magore

1962: production of a POM co-polymer invented by Celanese

Properties

POM combines high stiffness and strength with outstanding resilience, favourable sliding friction behaviour and excellent dimensional stability, even under the effect of mechanical forces, in contact with numerous chemicals,fuels and other media as well as at elevated temperatures.

Applications

- Consumer items

Expresso coffee brewing machines, children’s toys

- Electrical industry

Gas meters, disposable applicators, medical technology

- Automotive industry

Fuel tank modules, gear wheels, loudspeaker grills

Processes

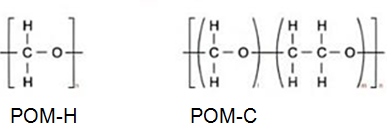

Polyacetal are semi-crystalline thermoplastics which are produced by homo- or co-poly-merisation of formaldehyde. The chemical structures are illustrated as follows:

Recycling

POM applications are 100% recyclable, either mechanically or as feedstock, and energy from waste can be recovered at incineration plants.

The most appropriate recovery options depend on numerous conditions. These include local legislation, plastics part design, access to sorting facilities and regional logistics and recycling costs.