Polyarylsulfone (PSU/P/PPSU)

PSU/P/PPSU is a thermally stable thermoplastic consisting mainly of phenyl and biphenyl groups linked by ether and sulfone groups. The material is resistant to high and low temperatures, has excellent impact strength, and is chemical and solvent resistant. It is, therefore, a popular choice for electrical insulation applications

- History

- Properties

- Applications

- Processes

- Recycling

- Faq

History

1980: Start of industrial production

Properties

Parts made out of polyarylsulfones have excellent dimensional stability and remain strong, rigid, and tough up to temperatures close to the glass transition temperature. The key features are:

- temperature-independent properties

- very high long-term service temperatures

- good dimensional stability

- high stiffness

- high mechanical strength

- good electrical insulation properties

- favorable dielectric properties

- very good fire behaviour

- excellent hydrolysis resistance

Applications

Polyarylsulfone is used in the automotive industry for:

- headlights and interior reflectors

Polyarylsulfone is used in the electrical and electronics industry for:

- fuse encapsulation

Elsewhere, polyarylsulfone is used to make:

- water fittings pump impellors baby bottles microwave dishes thin hollow fibres for water treatment

Processes

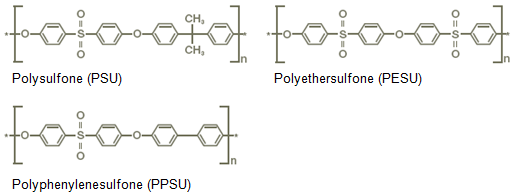

Polyarylsulfones are amorphous, thermoplastic polycondensation products with the following basic structures:

Recycling

Polyarylsulfone applications are 100% recyclable, either mechanically or as feedstock, and energy from waste can be recovered at incineration plants.

The most appropriate recovery options depend on numerous conditions. These include local legislation, plastics part design, access to sorting facilities and regional logistics and recycling costs.