Polyimide (PI)

PI is a polymer of imide monomers. Typical monomers include pyromellitic dianhydride and 4,4'-oxydianiline.

According to the composition of their main chain, polyimides can be:

- Aliphatic (linear polyimides)

- Semi-aromatic

- Aromatic: R' and R" are two carbon atoms of an aromatic ring. These are the most used polyimides because of their thermostability.

According to the type of interactions between the main chains, polyimides can be:

- Thermoplastic: very often called pseudothermoplastic

- Thermosetting: commercially available as uncured resins, polyimide solutions, stock shapes, thin sheets, laminates and machined parts.

- History

- Properties

- Applications

- Processes

- Recycling

- Faq

History

Polyimides have been in mass production since 1955.

Properties

Thermosetting polyimides are known for:

- thermal stability

- good chemical resistance

- excellent mechanical properties

- characteristic orange/yellow color.

Thermoset polyimides exhibit very low creep and high tensile strength.

Molded polyimide parts and laminates have very good heat resistance.

Polyimides are also inherently resistant to flame combustion and do not usually need to be mixed with flame retardants.

Typical polyimide parts are not affected by commonly used solvents and oils — including hydrocarbons, esters, ethers, alcohols and freons.

They also resist weak acids but are not recommended for use in environments that contain alkalis or inorganic acids.

Some polyimides are solvent-soluble and exhibit high optical clarity. The solubility properties lend them towards spray and low temperature cure applications.

Applications

Polyimides are used

- in the electronics industry for flexible cables

- as an insulating film on magnet wire

- for medical tubing

- PI film on magnet wire

The semiconductor industry uses polyimide as a high-temperature adhesive.

It is also used as a mechanical stress buffer. Some polyimide can be used like a photoresist.

An additional use of polyimide resin is as an insulating and passivation layer in the manufacture of digital semiconductor and microelectromechanical systems (MEMS) chips.

Polyimide powder can be used to produce parts and shapes by sintering technologies (hot compression moulding, direct forming, and isostatic pressing). Because of their high mechanical stability even at elevated temperatures they are used as bushings, bearings, sockets or constructive parts in demanding applications.

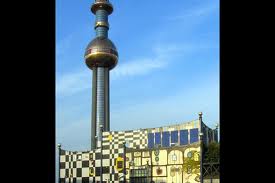

In coal-fired power plants, waste incinerators or cement plants, polyimide fibres are used in hot gas filtration. A polyimide needle felt separates dust and particulate matter from the exhaust gas.

Processes

Several methods are possible to prepare polyimides, among them:

- The reaction between a dianhydride and a diamine (the most used method)

- The reaction between a dianhydride and a diisocyanate.

- Examples of dianhydrides are pyromellitic dianhydride and naphthalene tetracarboxylic dianhydride.