Polyamide (PA)

PA is a semi-crystalline polymer.

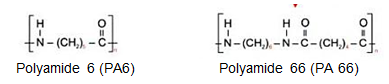

There are two types: those made of one basic material (e.g. PA 6) and those made of two basic materials (e.g. PA 66). They can occur both naturally (e.g. wool and silk) and synthetically (e.g. nylon).

Polyamides have excellent mechanical properties and can be either hard and tough or soft and flexible. They absorb moisture and have excellent slide and wear characteristics. Polyamides are commonly used in the textile and automotive industry.

- History

- Properties

- Applications

- Processes

- Recycling

- Faq

History

1930s: Beginning of methodical research of polyamides with the development of an industrial process for polyamide 6.6 (nylon) by W.H. Carothers and Polyamide 6 (perlon) by P.Schlack.

1940: Beginning of production

Between 1956-1965: Production increased significantly when highly stabilised polyamides (which could easily be processed) were developed

Since 1965: a number of refinements have been made including glass fibre reinforced polyamide compounds which are flame retardant.

Properties

- High mechanical strength

- Stiffness

- Thermal stability

- Tough at low temperatures

- Excellent resistance to chemicals

- Features a favourable sliding friction behaviour

- Permits problem-free processing.

Applications

Polyamides are used in the automotive industry for:

- oil pan

- transmission cross beams

- air intake manifolds

- crash-active engine covers

In the electric/electronics industry they are used for:

- photovoltaic connectors

- cordless hammer drills

- control modules for washing machines

- circuit breakers dowels

Processes

Polyamides for injection molding and extrusion include PA 6 grades, PA 66 grades as well as special polyamides such as partially aromatic polyamides mainly 6T based, PA6.10, PA6.12, PA11, PA12, PA46, etc.

Around 80% of the market is covered by PA 6 and PA 66 grades whereas the former is produced by hydrolytic polymerization of caprolactam and the latter by condensation polymerization of hexamethylene diamine and adipic acid. These materials are obtained from petrochemical feedstocks such as benzene, cyclohexane and p-xylene.

Recycling

Polyamide is 100% mechanically and feedstock recyclable. Our products can also be recovered in state-of-the-art incineration plants by generating energy.

The most appropriate recovery options depend on many boundary conditions such as local legislation, plastics part design, access to sorting facilities and regional logistics and recycling costs.