Epoxy Resins

Epoxy Resins: their physical state can be changed from a low viscosity liquid to a high melting point solid, which means that a wide range of materials with unique properties can be made

- History

- Properties

- Applications

- Processes

- Recycling

- Faq

History

Epoxy resins have been around for over 50 years, and are one of the most successful of the plastics families. Their physical state can be changed from a low viscosity liquid to a high melting point solid, which means that a wide range of materials with unique properties can be made. In the home, you’ll find them in soft-drinks cans and special packaging, where they are used as a lining to protect the contents and to keep the flavour in. They are also used as a protective coating on everything from beds, garden chairs, office and hospital furniture, to supermarket trolleys and bicycles! Most industries use them in protective coating materials. They are used, for example, in special paints to protect the surfaces of ships and oil rigs from bad weather and also in wind turbines!

Properties

As a family of synthetic resins, their physical state can be anything from a low viscosity liquid to a high melting point solid. 'Cross-linked' with a variety of curing agents or hardeners, they form a range of materials with a unique combination of properties, which make a considerable contribution to practically every major industry

Applications

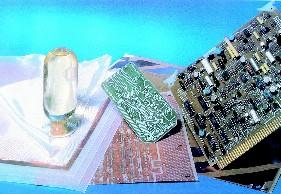

The applications for epoxy-based materials are extensive and include coatings, adhesives and composite materials such as those using carbon fiber and fiberglass reinforcements. The chemistry of epoxies and the range of commercially available variations allows cure polymers to be produced with a very broad range of properties. In general, epoxies are known for their excellent adhesion, chemical and heat resistance, good-to-excellent mechanical properties and very good electrical insulating properties. Many properties of epoxies can be modified (for example silver-filled epoxies with good electrical conductivity are available, although epoxies are typically electrically insulating). Variations offering high thermal insulation, or thermal conductivity combined with high electrical resistance for electronics applications, are available.

• Paints and coatings

• Adhesives

• Industrial tooling and composites

• Electrical systems and electronics

• Consumer and marine applications

• Aerospace applications

• Biology

• Art